White Phosphorus Bomb Protected Fabric

White Phosphorus Bomb Protected Fabric is made of silicone coated fiberglass fabric.

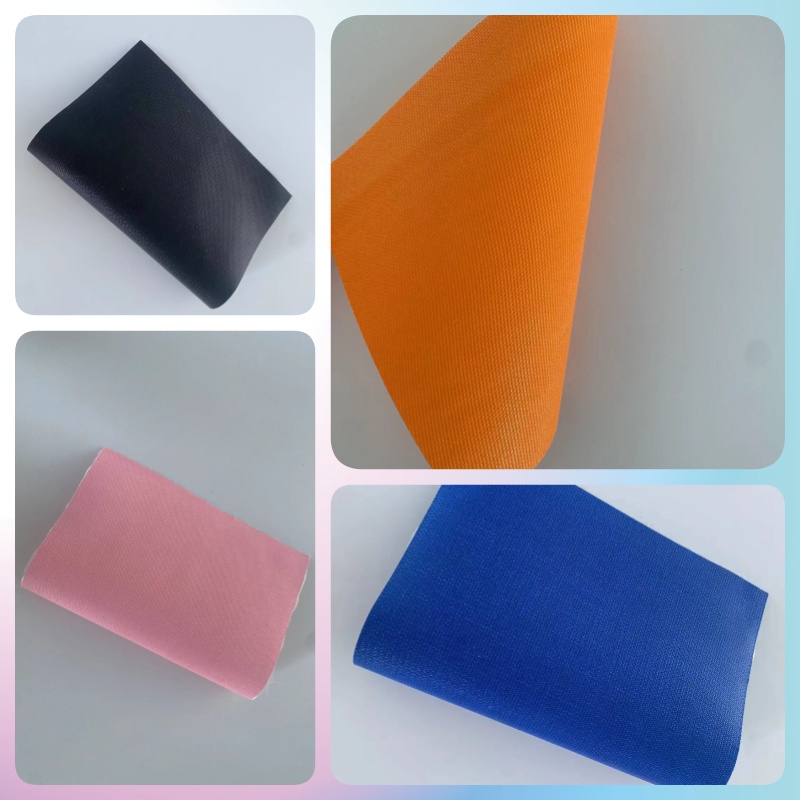

Grey, red, black, white, pink, blue, yellow or customized.

White Phosphorus Bomb Protected Fabric

White Phosphorus Bomb Protected Fabric is made of silicone coated fiberglass fabric.

Features:

I. Silicone coating process: internal and external double-layer process, outer silicone coating, inner glass fiber cloth, safer and more durable.

II. Flame retardant: Class A non-combustible, easy to cope with daily open fire and industrial fire.

III. Waterproof and oil proof: good airtight performance, better protection of thermal insulation cotton, not sticky oil stains, easy to take care of.

IV. Voltage resistance: High voltage insulation level, withstand higher voltage load, cable cover breakdown resistance.

V. Soft and easy to cut: easy to cut on demand, easy to apply to various occasions, consistent quality.

VI. Corrosion resistance and oxidation resistance: acid and alkali resistance and a variety of organic solvent corrosion, harsh use environment can also be competent, UV protection, long service life.

VII. Environmental protection and non-toxic: non-toxic, non-polluting, odorless, non-irritating to the skin, environmentally friendly

VIII. Rich color, color card customization: Support RAL color card customization, rich and colorful, easy to distinguish, add color to the world.

White Phosphorus Bomb Protected Fiberglass Fabric is a specially designed protective fabric that is mainly used to protect against the toxic gases and high temperatures released by white phosphorus bombs (WP Bombs) in war and military environments. This fabric combines the high heat resistance of glass fiber with special chemical treatment to effectively protect personnel and equipment from damage caused by white phosphorus bombs.

White phosphorus is a highly reactive chemical that releases toxic phosphorus fumes when it explodes or burns. Its extremely high heat can quickly ignite anything it touches. Therefore, the development of materials that can effectively isolate and protect this danger is crucial for military, emergency response and disaster relief.

Product Features and Characteristics

High temperature resistance:

Glass fiber itself has excellent high temperature resistance and can withstand temperatures up to 800°C, which is crucial for protecting against the high temperatures generated by white phosphorus combustion.

Chemical protection:

This material has been specially chemically treated to effectively isolate the invasion of white phosphorus vapor and prevent toxic phosphorus fumes from causing damage to humans and equipment.

Flame retardancy:

Glass fiber fabric itself has good flame retardancy, which can effectively prevent the material from spontaneous combustion and delay the spread of fire when facing a fire source.

Abrasion resistance:

Glass fiber fabric has high strength, excellent wear resistance, and can withstand the use conditions in complex environments.

Lightweight and high strength:

Compared with traditional metal protection materials, glass fiber fabric is lighter and easier to operate, and can provide effective protection without adding too much burden.

Chemical corrosion resistance:

Glass fiber material itself has strong chemical corrosion resistance, can resist the erosion of acid, alkali and other chemical substances, and maintain a long service life in harsh environments.

Breathability:

Due to its fiber characteristics, glass fiber fabric has a certain breathability, which can effectively reduce the accumulation of heat and water vapor, and enhance wearing comfort while maintaining protective performance.

| Parameter | Description |

| Material | Fiberglass (typically E-glass) |

| Temperature Resistance | Can withstand temperatures above 800°C |

| Thickness | 0.3 - 1.2 mm (depending on application) |

| Tensile Strength | Approximately 1000 - 3000 N (varies by weave) |

| Weight | 200 - 800 g/m² (depends on thickness) |

| Flammability | Non-flammable, meets international standards |

| Chemical Resistance | Good resistance to acids, alkalis, and chemicals |

| Dimensions | Customizable as per client requirements |

| Surface Treatment | Special chemical treatment for white phosphorus vapor protection |

Application scope and scenarios

Military protection:

This material is mainly used in the military field, especially in occasions such as white phosphorus bombs and chemical weapons that pose a serious threat to the environment and personnel. It is widely used in military protective clothing, tents, vehicle covering, command post protection, etc. to protect soldiers and military facilities from the harm of white phosphorus bombs.

Disaster relief:

In emergency response after disasters such as white phosphorus bombs or chemical leaks, rescuers can wear equipment made of this protective fabric for protection to ensure survival safety in high temperature and toxic gas environments.

Petrochemical industry:

Leakage accidents of white phosphorus or other harmful chemicals may occur in the petrochemical industry. The use of this protective fabric can effectively prevent injuries when exposed to these dangerous substances.

Aerospace:

In military aviation, protection against white phosphorus bombs is also a key technology. The use of this protective fabric can protect aircraft, helicopters and other equipment from damage caused by white phosphorus bomb explosions.

Special protective equipment:

This fabric can also be used to make protective barriers, shelters, emergency equipment, etc., to provide short-term protection for emergency personnel when facing chemical attacks.

Silicone coated fiberglass fabric is a versatile and high-performance material t...

View MorePVC coated fiberglass cloth is a high-performance composite material that combin...

View MorePTFE (polytetrafluoroethylene) glass fiber cloth is a high-performance composite...

View MorePVC Coated Tarpaulin Fiberglass Fabric plays a variety of important roles in the...

View MoreIf you are interested in our products or have any questions, please consult us.