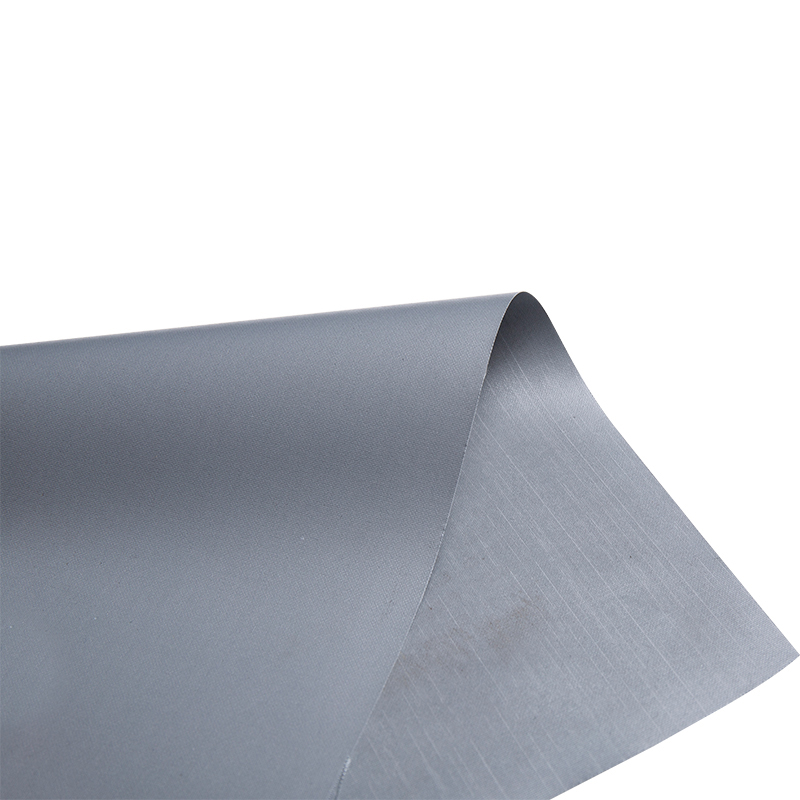

PVC Coated Air Duct Fabric, or PVC coated air duct fabric, is a flexible duct for air delivery, widely used in ventilation, exhaust, air flow and other environments. It is made of reinforced fiberglass fabric and treated with PVC coating to improve its weather resistance, chemical resistance and mechanical properties. The outer layer of this product is coated with PVC (polyvinyl chloride), which makes it waterproof, oil-proof, dust-proof and corrosion-resistant.

Main characteristics and parameters

Material:

Lining material: High-strength fiberglass fabric is used, which has strong high temperature resistance and wear resistance.

Coating material: The outer coating uses PVC (polyvinyl chloride), which has good UV resistance, oxidation resistance, waterproofness and chemical corrosion resistance.

Temperature range: The general temperature range is **-20°C to +90°C**. For some special specifications, the temperature resistance can be as high as 150°C.

Compressive strength: The high-strength fiberglass reinforced design makes the pipe have high compressive strength and good tensile resistance.

Flexibility: This type of duct has good flexibility, can be bent and twisted according to installation requirements, and will not break, which is suitable for ventilation ducts that require bending or complex paths.

Fire resistance: The combination of PVC coating and glass fiber makes this duct have good flame retardant properties and meets international fire protection standards.

Corrosion resistance: It has excellent resistance to a variety of chemicals, oils and moisture, and is suitable for harsh environments.

Weight and sealing: The light weight is easy to carry and install, and the duct has good sealing, which effectively avoids air leakage.

Anti-ultraviolet performance: It is particularly suitable for outdoor environments because the PVC coating has strong anti-ultraviolet ability and is not easy to age.

Application scenarios and fields

Ventilation system: It is widely used in air delivery systems in industrial and commercial buildings, especially those places that require flexible layout, such as factories, workshops, laboratories, etc.

Exhaust system: It is suitable for exhaust equipment and exhaust gas emission systems, which can effectively transport air or exhaust gas and avoid the spread of harmful substances.

Air conditioning system: In the air conditioning system, it is used as a connecting pipe for air conditioning units, suitable for high-flow air delivery.

Cleanroom and high temperature environment: PVC coated air ducts are also widely used in cleanrooms, electronic manufacturing workshops, laboratories and other places that require clean and dust-free air.

Food processing and pharmaceutical industries: Industries with high requirements for hygiene and sterility, such as food processing plants, pharmaceutical plants, etc., are used for air delivery or exhaust.

Automobile and machinery manufacturing: In the process of automobile manufacturing, it is used for the transmission of air and exhaust gas, helping to discharge exhaust gas or deliver fresh air.

Chemical and petrochemical industries: PVC coated air ducts can resist corrosion, so they are suitable for use in environments such as chemical plants and petrochemical plants to transport chemical gases and substances.

Spraying and drying equipment: Used for air transmission during spraying and drying to help maintain smooth airflow and prevent air pollution.

English

English عربى

عربى 中文简体

中文简体 Languages

Languages