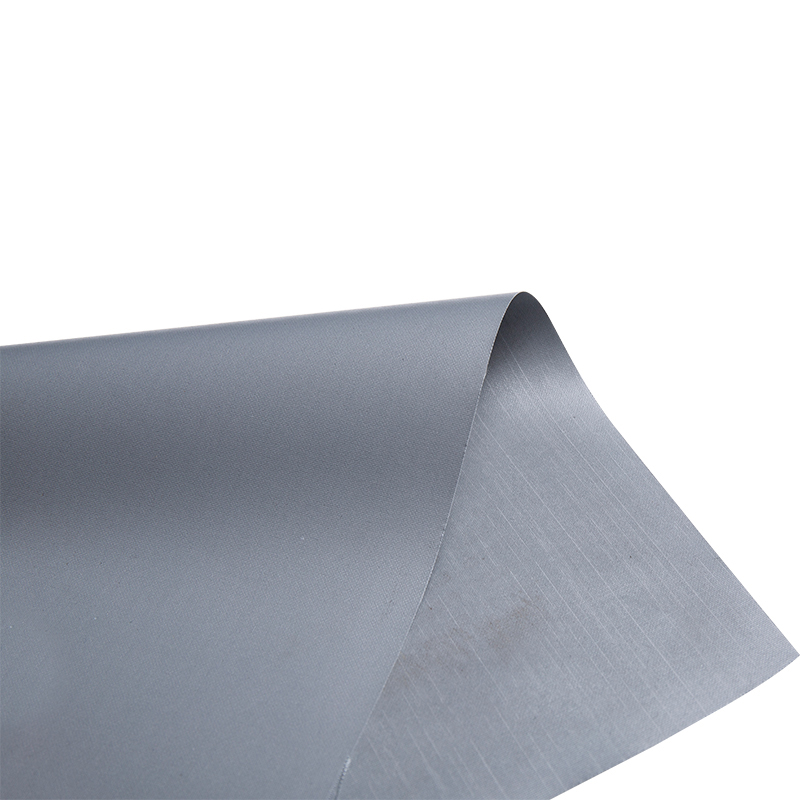

Polytetrafluoroethylene (PTFE) membrane, derived from the synthetic fluoropolymer PTFE, stands as a testament to the remarkable capabilities of engineered materials. This microporous marvel, with its intricate structure consisting of densely packed nodes interconnected by fibrils, boasts exceptional filtration capabilities that have found applications across a spectrum of industries. Its outstanding chemical resistance, thermal stability, and low friction characteristics combine to make it an indispensable element in applications that demand nothing short of exceptional performance. The PTFE membrane's profound impact is evident in fields such as water and air filtration, medical devices, and high-performance apparel.

Unveiling the Properties and Applications

Central to the widespread adoption of PTFE membranes is their unparalleled chemical resistance. PTFE's inherent non-reactivity to aggressive substances makes the membrane impervious to a wide range of corrosive chemicals, rendering it invaluable in situations where exposure to harsh substances is a constant. The microporous architecture of the membrane enhances its utility by facilitating selective molecular passage based on size and chemical properties. This, in turn, has led to its application in critical processes such as microfiltration in the pharmaceutical industry, where even the minutest particles must be separated with precision, as well as in the separation of complex mixtures of water and organic solvents in the chemical industry.

However, the prowess of PTFE membranes extends beyond chemical resistance. They exhibit remarkable thermal stability, demonstrating the ability to withstand extreme temperatures without degradation, making them well-suited for applications in challenging environments. Additionally, the membrane's low coefficient of friction, combined with its water-repellent nature, results in a self-cleaning phenomenon. When liquids come into contact with the membrane, they form droplets that readily roll off, carrying away accumulated contaminants. This property finds utility in air filtration systems designed for pollution control, where sustained efficiency is crucial, as well as in the production of outdoor clothing that remains resistant to water and dirt.

Innovations and Future Trajectories

The production of PTFE membranes involves a blend of specialized techniques aimed at achieving the desired microporous structure. One common method involves paste extrusion, where PTFE resin is mixed with a lubricant and then extruded to form a semi-porous membrane. Subsequent removal of the lubricant leaves behind the porous structure. Another approach entails stretching a PTFE film to create pores of controlled sizes. Recent advancements have led to the development of composite membranes, where a PTFE layer is combined with other materials to enhance specific properties. For instance, combining PTFE with hydrophilic polymers can modify the membrane's wetting behavior, making it suitable for applications where controlled liquid transport is required, such as in medical devices.

Continued research is focused on refining the properties of PTFE membranes. Efforts are aimed at enhancing factors like pore size distribution, filtration efficiency, and mechanical durability. The incorporation of nanotechnology has ushered in a new era of possibilities, allowing for the fine-tuning of membrane properties at the nanoscale. As technology advances, PTFE membranes are poised to find new horizons of application and contribute to innovations across industries.

Ptfe Membrane Material

English

English عربى

عربى 中文简体

中文简体 Languages

Languages