Fiberglass is an incredibly adaptable composite material used in a range of products. This versatility stems from its dual nature as an amalgamation of plastic resin and glass fibers - giving designers greater freedom when selecting materials best suited to achieving specific end uses.

Fiberglass composite materials combine two separate elements to produce an extremely lightweight yet strong and durable lightweight material, suitable for many different industries and uses. Fiberglass can also be molded into complex shapes for use across many applications due to its inherent versatility; making this an excellent choice for industries whose specific design requirements would otherwise make production impossible or cost prohibitive using traditional materials.

Glass fibers are used extensively in boat building. Fiberglass has become one of the primary building materials for recreational boats and fishing vessels alike.

Fiberglass has long been used in aerospace. Airplane wings, spacecraft wings and missile wings often employ fiberglass components; fuselages, engine compartments and landing gears often also employ this material.

Fiberglass's strength and durability makes it a popular choice for utility poles as well as electrical equipment, particularly electrical distribution poles. Due to its dielectric strength, arc resistance, mechanical toughness, and nonconductive nature, fiberglass materials offer protection from damage or degradation of cables or wires while remaining nonconductive to electricity - perfect for keeping cables safe.

In the building industry, fiberglass can be found being utilized to produce roof laminates, door surrounds and window canopies. Furthermore, fiberglass has its uses in building chimneys with coping systems or heads with sills and keystones attached as well as heads with sills and keystones attached with keystones topped off with sills or keystones; in cladding systems combined with insulation it helps lower energy costs further still.

Fiberglass is an extremely cost-effective composite material to produce, often costing less than wood or metal and less susceptible to corrosion than either. Furthermore, fiberglass stands up well under various environmental conditions.

One drawback of fiberglass is its resin content, which may contract during curing and cause distortions to the final product. While this issue can be mitigated with careful placement of the fiberglass sheets, designers must still keep this in mind when planning projects using fiberglass materials.

Pultrusion is an affordable method of producing fiberglass products, employing large furnaces to gradually melt all of its ingredients - such as silica, sand, limestone, kaolin clay, fluorspar and boric acid - together. Once this liquid mixture has formed, it's then pulled through heated dies into whatever desired shape is desired - an extremely efficient manufacturing method, especially when dealing with large parts with complex shapes.

Glass fiber can be used in numerous ways; its uses are only limited by your imagination. Most are familiar with its application in DIY projects like building boats, surfboards or home siding panels; while commercial facilities often utilize it such as amusement parks, water slides and even bathtubs in gyms or health clubs.

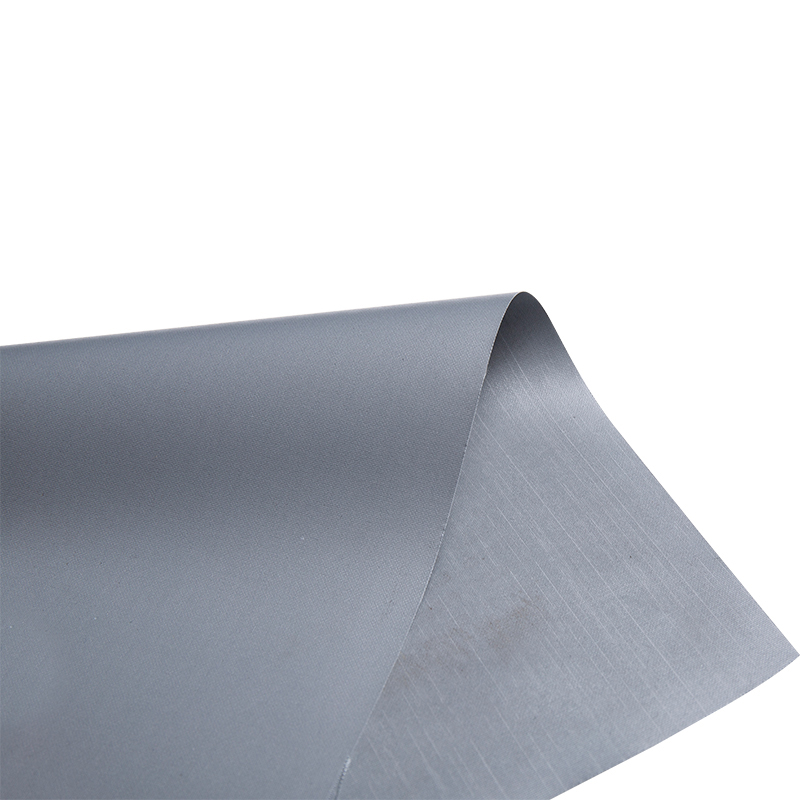

Carbon Fabric

Carbon Fabric

English

English عربى

عربى 中文简体

中文简体 Languages

Languages