In the oil and gas extraction and processing process, due to the involvement of a variety of corrosive media, is Silicone Coated Fiberglass Fabric suitable for making protective layers for storage tanks, pipelines and equipment to extend their service life?

In oil and gas extraction and processing, the presence of corrosive media is indeed an important factor to consider. These media may include various acids, alkalis, salts, and organic solvents. Their corrosive effects on equipment and pipelines will seriously affect their service life and safety.

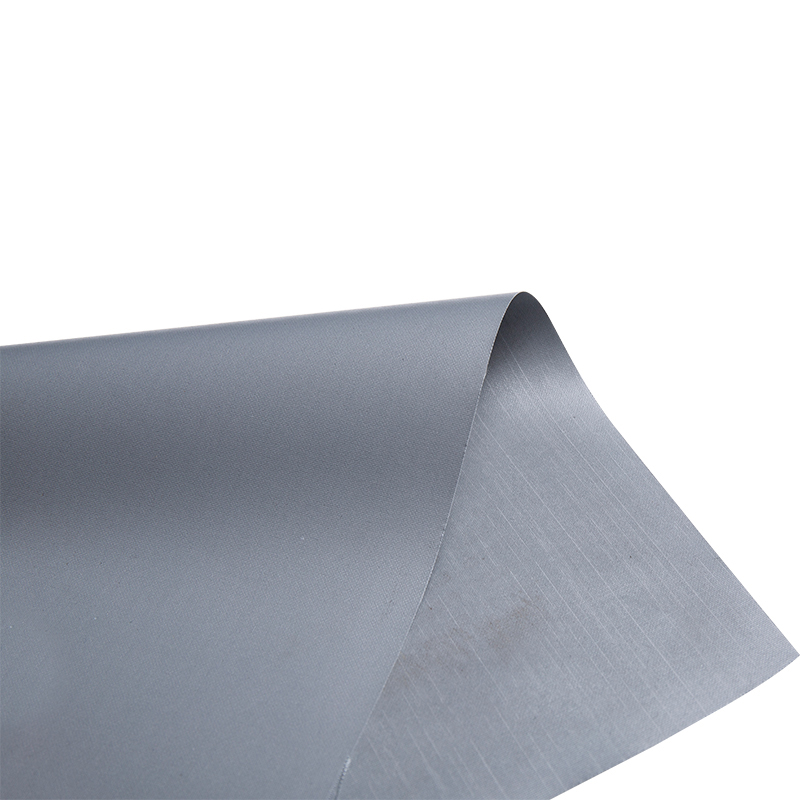

Silicone Coated Fiberglass Fabric is a material with excellent chemical resistance. Silicone coatings can effectively resist the attack of many chemicals and provide long-term protection for the substrate. At the same time, the silicone coating also has good temperature resistance and can maintain stable performance over a wide temperature range.

For storage tanks, pipelines and equipment in oil and gas extraction and processing, using Silicone Coated Fiberglass Fabric as a protective layer has the following advantages:

Chemical corrosion resistance: Silicone coating can effectively resist the erosion of various corrosive media, reduce the corrosion rate of equipment and pipelines, thereby extending their service life.

Good temperature resistance: Silicone coating can maintain stable performance over a wide temperature range and is suitable for high and low temperature environments in oil and natural gas exploration and processing.

Good flexibility and adhesion: Silicone Coated Fiberglass Fabric has good flexibility and adhesion, and can closely adhere to the surface of equipment and pipes to form an effective protective layer.

Easy construction: Silicone-coated glass fiber cloth can be easily constructed by brushing, spraying, etc., with a short construction period and low cost.

However, when choosing to use Silicone Coated Fiberglass Fabric as a protective layer, you need to pay attention to the following points:

Coating thickness: The coating thickness should be determined according to the specific use environment and the type and concentration of corrosive media to ensure adequate protection.

Pretreatment: Before applying the silicone coating, the equipment and pipe surfaces need to be pretreated, such as cleaning, rust removal, etc., to ensure the tight combination of the coating and the base material.

Regular inspection and maintenance: Even if a protective layer is used, equipment and pipelines need to be inspected and maintained regularly to detect and deal with potential corrosion problems in a timely manner.

Silicone Coated Fiberglass Fabric has great application potential as a corrosion-resistant protective layer material in oil and natural gas extraction and processing. Through reasonable selection and use, the service life of storage tanks, pipelines and equipment can be effectively extended, and the safety and stability of the entire production system can be improved.

English

English عربى

عربى 中文简体

中文简体 Languages

Languages