In the chemical industry, how is Silicone Coated Fiberglass Fabric used in the protection of chemical equipment and pipe wrapping to resist erosion and corrosion from chemical substances?

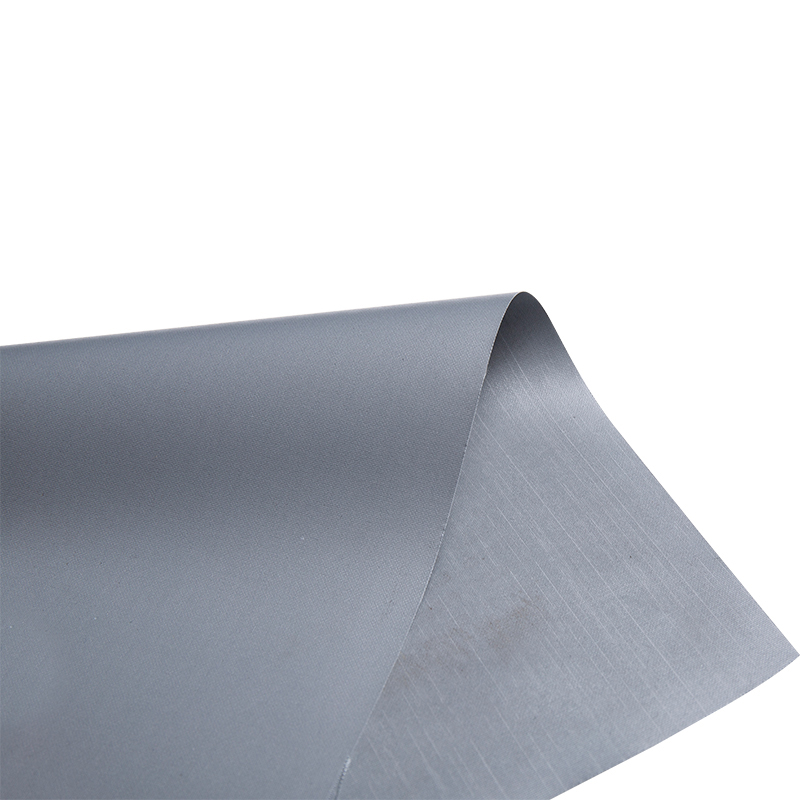

In the chemical industry, Silicone Coated Fiberglass Fabric has become an ideal choice for chemical equipment protection and pipe wrapping due to its unique chemical resistance. Here is a detailed description of how it is applied and how it resists chemical attack and corrosion:

1. Chemical equipment protection

Protective layer application: Silicone Coated Fiberglass Fabric can be used as a protective layer for chemical equipment, directly covering the surface of the equipment. Its silicone coating can effectively resist the erosion of various chemicals, such as acids, alkalis, salts, etc., protecting equipment from corrosion.

Enhanced structural strength: The addition of Fiberglass Fabric makes this material have high tensile strength and flexibility, which can enhance the structural strength of the device and improve the device's resistance to external stress and impact.

High temperature resistance: In some chemical processes, equipment may be subjected to high temperatures. Silicone Coated Fiberglass Fabric has good high temperature resistance and can maintain stable performance in high temperature environments, providing long-lasting protection for equipment.

2. Pipe wrapping

Anti-corrosion wrapping: By wrapping Silicone Coated Fiberglass Fabric on the outer surface of the pipe, an effective anti-corrosion barrier can be formed to prevent direct contact between chemicals and the pipe, thereby extending the service life of the pipe.

Thermal insulation: In addition to its anti-corrosion function, this material also has certain thermal insulation properties. It can reduce heat loss when pipelines transport high-temperature or low-temperature chemicals and improve energy efficiency.

Easy to install and maintain: Silicone Coated Fiberglass Fabric is lightweight and flexible, making its installation process relatively easy. At the same time, its surface is smooth and does not easily adhere to dirt and dust, making it easy to clean and maintain.

By applying Silicone Coated Fiberglass Fabric to protect chemical equipment and wrap pipes, companies can significantly reduce equipment damage and repair costs caused by chemical corrosion, and improve production efficiency and safety. At the same time, the material's long life and ease of maintenance also bring long-term economic benefits to the company.

Heat Resists Emergency Fire Blanket With Carry Bag

Heat Resists Emergency Fire Blanket With Carry Bag

English

English عربى

عربى 中文简体

中文简体 Languages

Languages