How does the water resistance of PVC Coated Fiberglass Fabric make contributions to its suitability for precise industries, and what concerns should be taken under consideration while selecting this cloth for packages wherein water resistance is a important factor?

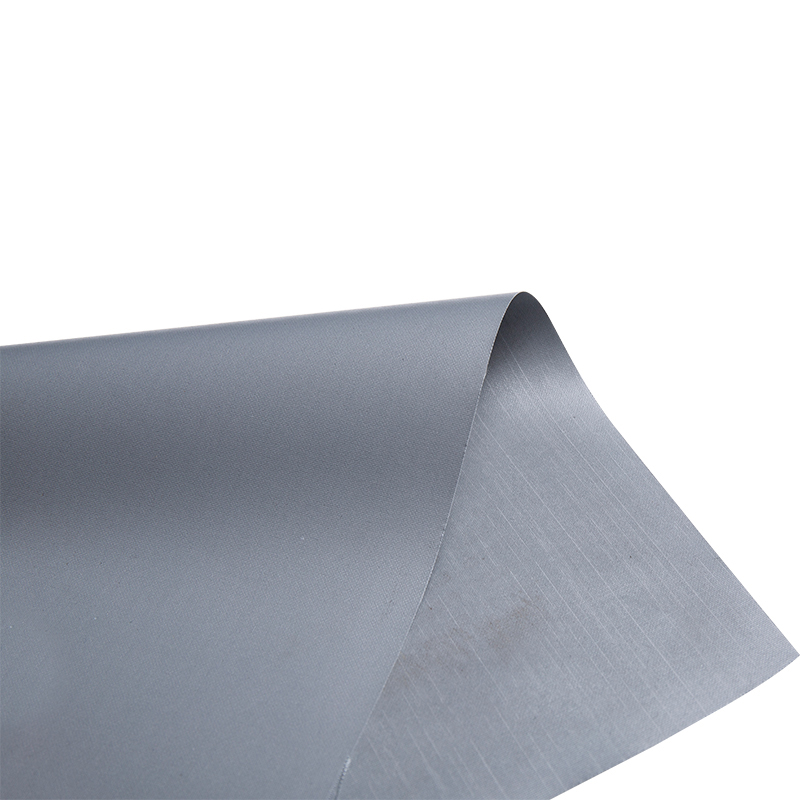

PVC covered fiberglass cloth's water resistance is a critical characteristic that notably impacts its suitability for a lot of industries and programs. The inherent properties of both fiberglass and PVC coating synergize to create a cloth that excels in situations where publicity to water is a situation.

1. Outdoor Applications:

One of the number one regions in which water resistance performs a important position is in out of doors packages. PVC coated fiberglass fabric is normally used inside the production of out of doors covers, canopies, and awnings. These materials should withstand the elements, together with rain, snow, and dew. The water resistant nature of the material guarantees that it acts as an effective barrier against moisture, stopping water from permeating and probably destructive the included objects.

2. Construction Industry:

In the development industry, where climate situations can be unpredictable, substances used for transient enclosures, protective obstacles, and production web page covers should be immune to water ingress. PVC coated fiberglass fabric, with its water-resistant homes, serves as an ideal choice for such programs. It helps keep the integrity of the development web site with the aid of stopping water damage to equipment, gear, and substances.

3. Agricultural Sector:

In agriculture, wherein equipment and components are frequently exposed to varying weather situations, the water resistance of PVC lined fiberglass material is valuable. It is usually hired within the creation of agricultural covers, including hay and device covers, protective essential sources from moisture that could result in degradation.

4. Marine and Boating Applications:

Given its water resistance, PVC lined fiberglass cloth unearths packages within the marine industry. It is used to manufacture covers for boats, marine device, and shielding enclosures. The cloth's potential to withstand water penetration is important in retaining the situation of marine belongings and stopping harm as a result of publicity to saltwater.

Considerations for Choosing PVC Coated Fiberglass Fabric with Water Resistance:

1. Waterproofing Levels:

Different programs may have various requirements for waterproofing. It is essential to don't forget the particular waterproofing level needed for the supposed use. Some applications may additionally require a higher stage of water resistance than others.

2. Environmental Exposure:

Understanding the environmental conditions to which the fabric might be exposed is important. For instance, fabric utilized in tropical climates may also need to face up to heavy rainfall, while the ones in arid regions may prioritize resistance to occasional rain and dirt.

3. Flexibility and Durability:

While water resistance is crucial, it is also essential to do not forget the material's normal flexibility and durability. A balance have to be struck to ensure the fabric remains flexible sufficient for its supposed software at the same time as providing strong protection against water.

4. Maintenance Requirements:

Consider the convenience of preservation, mainly if the fabric will be uncovered to challenging conditions. PVC covered fiberglass cloth with water resistance often allows clean cleaning, contributing to its toughness and overall performance through the years.

In conclusion, the water resistance of PVC lined fiberglass cloth is a crucial function that enhances its versatility across diverse industries. When selecting this cloth, knowledge the specific water resistance needs of the application and considering elements inclusive of environmental exposure, flexibility, and upkeep requirements are key to making sure gold standard performance and durability.

PVC Fiberglass Tarpaulin

PVC Fiberglass Tarpaulin

English

English عربى

عربى 中文简体

中文简体 Languages

Languages