In the food processing enterprise, how does the nonstick assets of PTFE fiberglass material make a contribution to operational efficiency and product excellent?

The nonstick houses of PTFE fiberglass fabric play a pivotal role in enhancing operational efficiency and making sure excessive product great in the meals processing enterprise. This particular characteristic addresses numerous challenges faced through manufacturers, undoubtedly impacting techniques ranging from baking to packaging.

One of the primary applications of PTFE fiberglass cloth within the food processing enterprise is within the manufacturing of baking sheets and mats. The nonstick floor prevents food objects, especially those with high sugar or fat content material, from adhering to the floor all through baking. This not only simplifies the discharge of finished merchandise however also minimizes the need for added oils or release marketers. Consequently, using PTFE fiberglass cloth contributes to more healthy food alternatives through reducing the overall fats content material within the final merchandise.

The nonstick property is particularly fine inside the manufacturing of baked items consisting of pastries, cookies, and bread. It guarantees that sensitive or sticky dough does no longer adhere to the baking surfaces, facilitating smooth removal and maintaining the integrity of the finished merchandise. Bakeries and big-scale food producers advantage from multiplied production performance as the nonstick belongings minimizes downtime associated with cleaning and scraping baking surfaces between batches.

Moreover, PTFE fiberglass cloth unearths application in conveyor belts inside food processing centers. The nonstick surface reduces the likelihood of food particles adhering to the belts for the duration of the transportation of merchandise through numerous levels of processing. This is essential for keeping hygiene requirements and preventing go-infection. Additionally, the decreased friction coefficient of PTFE contributes to smoother product go with the flow alongside the conveyor, minimizing put on and tear on system and ensuring constant product great.

In food packaging tactics, PTFE fiberglass cloth is employed inside the manufacturing of launch sheets. These sheets save you sticky or viscous products, consisting of chocolates or chocolate, from sticking to the packaging material. This no longer best enhances the aesthetics of the very last packaged product however also helps a more streamlined and efficient packaging method. The nonstick assets guarantees that every product is cleanly released from the packaging equipment, decreasing waste and improving usual packaging line performance.

Beyond manufacturing and packaging, the nonstick properties of PTFE fiberglass cloth also simplify cleaning processes. Equipment and surfaces covered with PTFE are simpler to clean as residues do no longer adhere strongly. This is in particular critical within the meals industry, in which maintaining high levels of cleanliness and hygiene is imperative.

In end, the nonstick houses of PTFE fiberglass cloth carry enormous advantages to the meals processing industry. From enhancing the efficiency of baking approaches to facilitating smooth product conveyance and enhancing the cleanliness of gadget, this characteristic positively affects both operational efficiency and the overall great of meals merchandise. As the industry continues to prioritize performance and pleasant, the usage of PTFE fiberglass material is probably to remain a key detail in optimizing various techniques inside the meals processing chain.

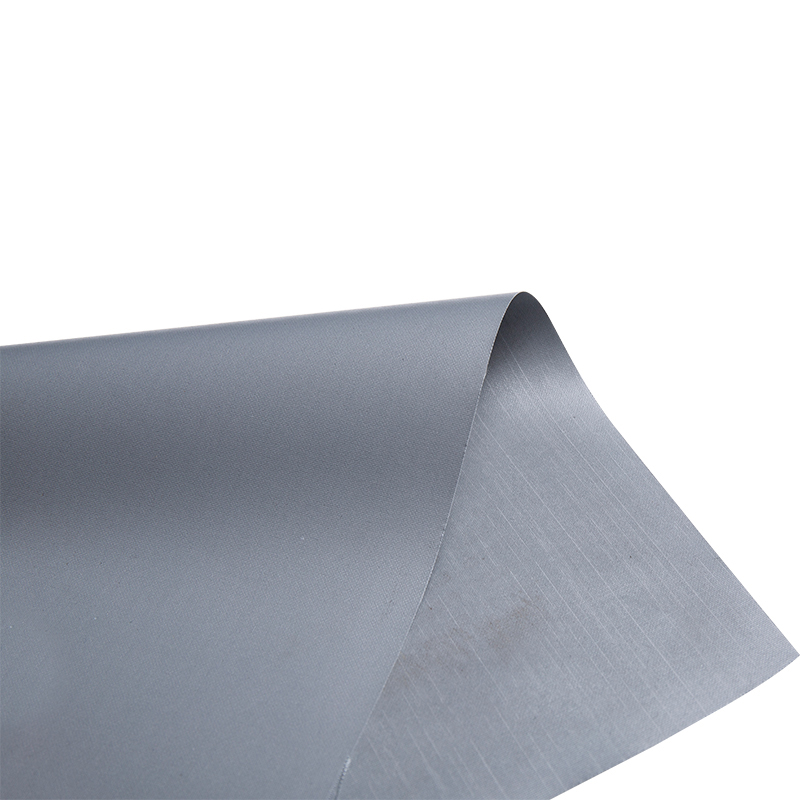

PTFE High Temperature Fabric

PTFE High Temperature Fabric

English

English عربى

عربى 中文简体

中文简体 Languages

Languages