The low coefficient of friction in PTFE mesh conveyor belts made from fiberglass cloth is a key characteristic that extensively contributes to improved efficiency in various commercial packages. This function plays a essential function within the clean and efficient motion of substances, impacting productiveness and universal overall performance. Let's delve into how the low coefficient of friction influences the performance of these conveyor belts in industrial settings.

The low coefficient of friction in PTFE mesh conveyor belt fiberglass cloth is a fundamental assets that brings about several blessings in industrial programs. This low coefficient of friction basically refers to the minimal resistance encountered when one floor (in this case, the conveyor belt) movements over every other surface. This property has profound implications for efficiency inside the following methods:

Smooth Material Transfer:

The number one gain of a low coefficient of friction is the easy transfer of substances along the conveyor belt. As materials flow across the surface with minimum resistance, there's much less wear and tear on each the belt and the transported items. This clean movement ensures a consistent and dependable flow of substances, decreasing the likelihood of jams or disruptions within the manufacturing procedure.

Energy Efficiency:

Low friction approach much less strength is needed to transport materials along the conveyor belt. This is specifically extensive in commercial settings wherein huge quantities of substances are transported over extended periods. Reduced frictional resistance interprets to lower electricity intake, contributing to strength efficiency and price savings for the operation.

Prevention of Material Adhesion:

The non-stick houses related to low friction are important in stopping substances from adhering to the conveyor belt. In industries inclusive of food processing and packaging, where cleanliness and hygiene are paramount, the low coefficient of friction minimizes the probability of product residues sticking to the belt. This now not only ensures a extra sanitary method but additionally enables easier cleansing and maintenance.

Extended Belt Lifespan:

Reduced frictional forces cause much less wear on the conveyor belt itself. As the belt stories less abrasion and strain during operation, its average lifespan is extended. This no longer simplest contributes to value savings via reducing the frequency of belt replacements however also enhances the overall reliability of the conveyor machine.

Consistent Production Rates:

The low coefficient of friction promotes regular and predictable cloth flow. This is in particular essential in production processes where precise timing and coordination are vital. By minimizing variations in cloth motion, the conveyor machine can maintain a steady manufacturing price, contributing to common operational performance.

Versatility in Applications:

The low frictional traits of PTFE mesh conveyor belts make them versatile for a extensive range of packages. Whether in excessive-temperature environments or industries in which chemical resistance is crucial, these belts maintain their low friction homes, adapting to numerous industrial wishes.

In end, the low coefficient of friction in PTFE mesh conveyor belt fiberglass fabric is a cornerstone feature that enhances the performance, reliability, and durability of conveyor systems in numerous industrial packages. This belongings, combined with other inherent characteristics of PTFE and fiberglass, positions these conveyor belts as valuable belongings throughout industries looking for top of the line material managing solutions.

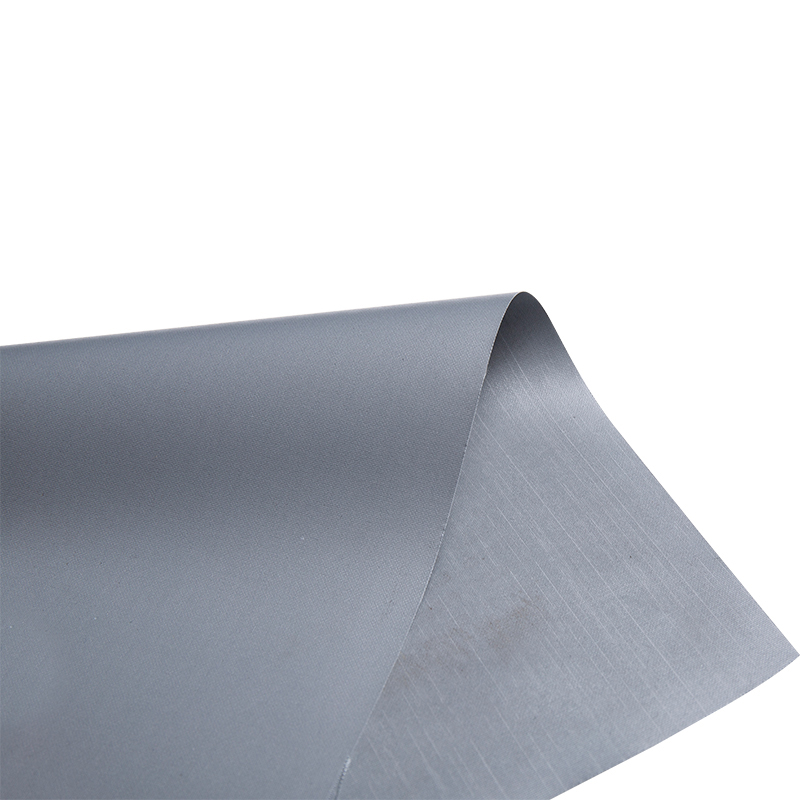

PTFE Fiberglass Mesh Conveyor Belt

PTFE Fiberglass Mesh Conveyor Belt

English

English عربى

عربى 中文简体

中文简体 Languages

Languages