The aerospace enterprise stands at the vanguard of technological innovation, continuously pushing the boundaries of what is workable in terms of overall performance, efficiency, and safety. One of the important thing techniques hired through aerospace engineers to fulfill those challenges is the utilization of composite substances with tailor-made homes.

Lightweight Design for Fuel Efficiency:

A important focus in aerospace engineering is the search for gasoline performance, given its direct effect on working charges and environmental sustainability. Composite substances, recognised for their high power-to-weight ratio, play a pivotal role in achieving lightweight designs. By carefully choosing the matrix and reinforcing materials and optimizing their distribution, engineers can reduce the general weight of plane systems with out compromising structural integrity. This weight loss translates to lower gasoline intake, accelerated variety, and advanced common efficiency.

Customizable Mechanical Properties for Structural Integrity:

Aerospace programs call for substances with unique mechanical homes to ensure structural integrity under various situations. Composites provide the benefit of customizable mechanical homes via the selection of reinforcement substances, their orientation, and the general composition. For instance, carbon fiber composites are regularly used for their high tensile power, presenting super resistance to the forces experienced during flight. By tailoring the composite composition, engineers can layout components that face up to the complicated and dynamic loading situations encountered in aerospace environments.

Thermal Management in Extreme Conditions:

Aerospace structures function in numerous thermal environments, starting from the intense bloodless of excessive altitudes to the extreme heat generated throughout supersonic flight. Composite materials may be engineered to cope with these demanding situations by using adjusting their thermal conductivity and insulation residences. For components uncovered to excessive temperatures, such as engine components or main edges of wings, composites with high thermal resistance can be hired. On the other hand, in areas where warmth dissipation is crucial, composites with stronger thermal conductivity may be used to effectively transfer warmth away from sensitive components.

Corrosion Resistance and Long-Term Durability:

Aircraft are subjected to harsh environmental conditions, which include exposure to moisture and corrosive elements. Traditional substances like aluminum are vulnerable to corrosion, main to upkeep demanding situations and decreased lifespan. Composite substances, inherently corrosion-resistant, provide a method to this issue. By incorporating composite structures in important additives, engineers can beautify the durability and toughness of aerospace structures, reducing protection charges and enhancing common reliability.

Design Flexibility for Aerodynamic Efficiency:

Aerodynamic efficiency is paramount in aerospace design, influencing elements inclusive of gas consumption and universal performance. Composite substances provide extraordinary layout flexibility, permitting engineers to create aerodynamically optimized shapes that can be tough or not possible to attain with traditional substances. The capability to mildew composites into complicated and streamlined bureaucracy contributes to the development of greater green and agile aircraft.

In end, the aerospace enterprise blessings significantly from the tailor-made residences of composite materials. These substances enable engineers to cope with precise challenges associated with weight, mechanical performance, thermal control, corrosion resistance, and aerodynamics. As the enterprise keeps to conform, the strategic use of composite substances will probable play an more and more indispensable role within the development of greater superior, efficient, and sustainable aerospace technology.

8sw1z0_{a~n)24(oj5)hdm-1.jpg?imageView2/2/format/jp2)

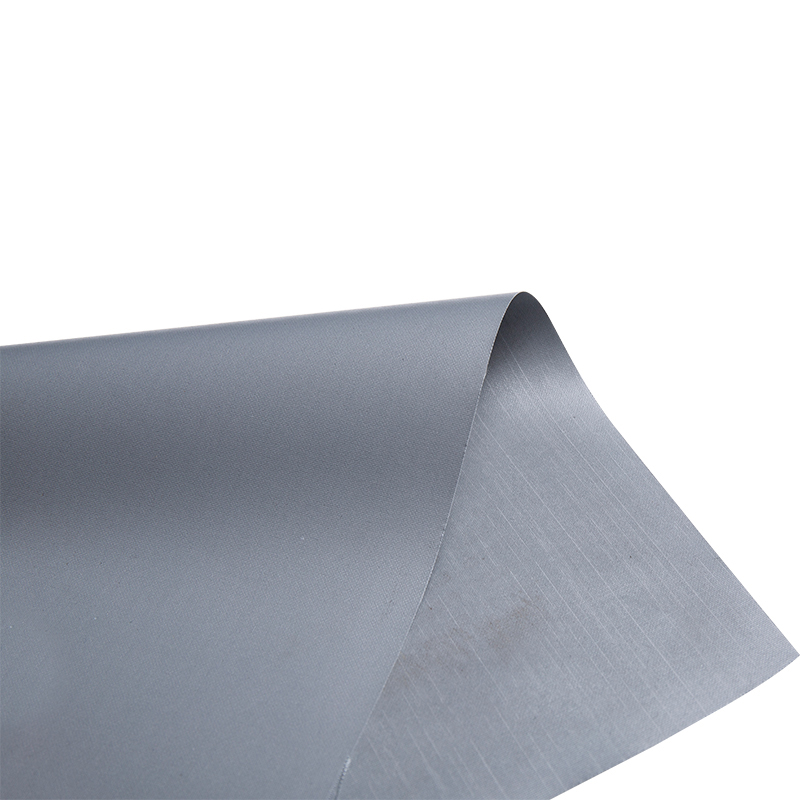

Carbon Fiber Fabric

8sw1z0_{a~n)24(oj5)hdm-1.jpg?imageView2/2/format/jp2)

Carbon Fiber Fabric

English

English عربى

عربى 中文简体

中文简体 Languages

Languages