Filter Fabric - The Unsung Hero of Gravel Driveways

Filter Fabric is the unsung hero of gravel driveways everywhere; its main role being to prevent weeds from sprouting through your gravel and prevent your driveway from turning into a mud pit after rainstorms. Furthermore, Filter Fabric serves multiple functions such as soil separation, stabilization and reinforcement as well as drainage filtration applications.

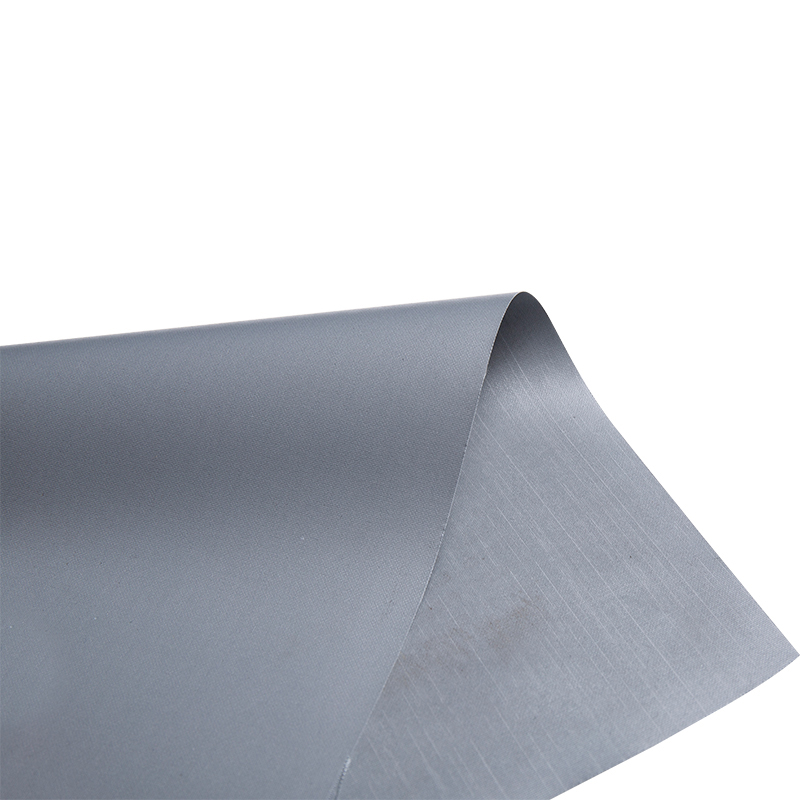

Filter fabric's primary purpose is to allow water through while blocking out debris such as sediment, silt, dirt and other fine materials. They come in an assortment of roll sizes and weights that give builders plenty of options when planning their projects. Furthermore, filter fabrics resist UV rays, rot and pressure well - providing plenty of durability when exposed to strain or pressure.

Filter fabrics are typically non-woven geotextiles, made of synthetics but not woven together as in traditional landscape or construction fabrics. Instead, these non-woven geotextiles are produced through needle punching; using barbed needles to punch holes into felt-like permeable geotextile fabrics that provide good strength while still offering good drainage properties; the advantages of non-woven geotextiles make them suitable for many separation and drainage type applications.

Gabion Supply offers several non-woven geotextile filter fabrics ranging in weight and purpose. Our most popular non woven polypropylene filter fabric, our 10 oz non woven polypropylene filter fabric is an ideal choice for all of your French Drain, ground cover and weed block needs in the garden. Highly breathable this fabric provides adequate drainage for plants as well as being suitable for laying beneath gravel or rock french drain systems for optimal performance.

Our selection of woven monofilament filter fabrics provides thicker and stronger filter solutions than needle punched non-wovens, ideal for projects requiring both strength and low clogging rates. Woven monofilaments have tighter weave than needle punched non-wovens while offering larger percent open areas than short staple fibers found in needle punched non-wovens.

Woven monofilament fabrics can also be an ideal solution for soil separation, sediment control and reinforcement applications that demand high strength but lower permeability than what non-wovens offer. They can be integrated under large rip-rap to control shoreline erosion; serve as cushioning layers in gabion walls or drainage zones of gabions walls; or prevent mixing of sand and ballast in railroad track foundations.

Both woven and non-woven filter fabrics can be coated with polymers to improve their permeability, strength, or erosion control properties. The coatings may either be sprayed on as liquid or laid down on a sheet that bonds directly onto the fabric surface - giving you greater control over its performance in your project. This allows more customized control of its performance.

Filter Fabric

Filter Fabric

English

English عربى

عربى 中文简体

中文简体 Languages

Languages