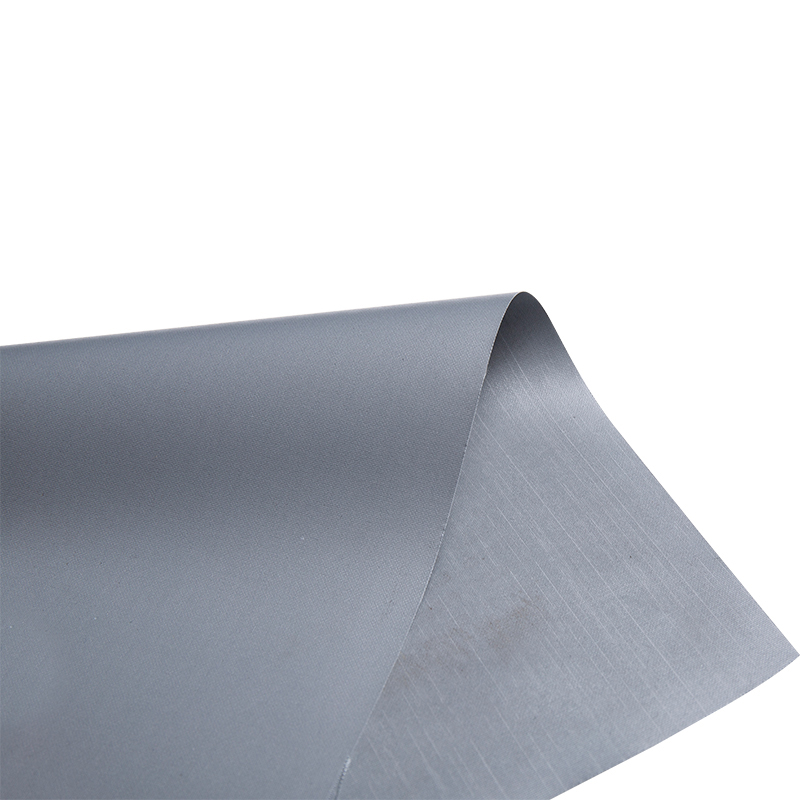

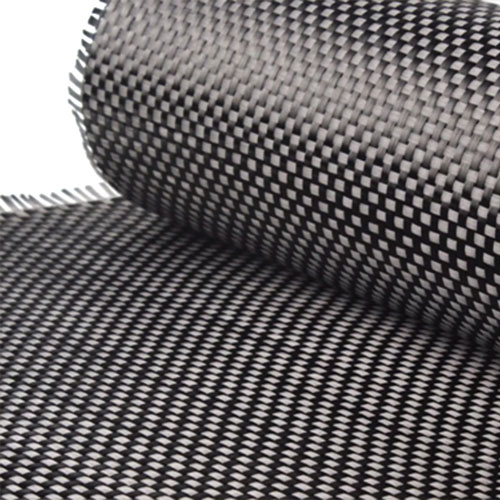

Carbon fabric, an embodiment of the exceptional properties of carbon fibers, stands as a transformative composite material. Comprising carbon atoms arranged in a crystalline lattice, carbon fibers boast unparalleled strength, low weight, and excellent thermal conductivity. When interwoven into fabric, these fibers create a versatile material with remarkable mechanical attributes. Its strength, lightweight nature, and adaptability have driven its incorporation across industries like aerospace, automotive, sports, and industrial manufacturing.

The Nexus of Strength, Weight, and Customization

Central to carbon fabric's allure is its unparalleled strength-to-weight ratio, underpinned by the inherent robustness of carbon fibers. The fabric’s capacity to endure substantial mechanical stress while remaining lightweight is particularly advantageous in sectors like aerospace, where efficiency and performance are paramount. Noteworthy is its exceptional thermal conductivity—a boon for applications necessitating efficient heat dissipation, such as electronics and thermal management systems. Additionally, carbon fabric’s resistance to corrosion renders it invaluable in challenging environments, including chemical processing, marine operations, and architectural endeavors.

Of equal significance is the fabric's inherent customization potential. The manipulation of weave patterns and fiber orientations empowers designers to optimize mechanical and structural characteristics, aligning the material precisely with intended usage. This malleability is evident in automotive design, where carbon fabric composites contribute to weight reduction and vehicle safety. In the realm of sports equipment, the fabric's stiffness and lightness offer enhanced performance in items like bicycles and tennis rackets. Its utilization in prosthetics underscores its contribution to improved quality of life by combining strength and lightweight construction for comfortable mobility.

Weaving Progress: Techniques and Innovations

The production of carbon fabric is achieved by intricately weaving carbon fibers into textile patterns. The specific weave employed significantly shapes the fabric's attributes, dictating strength, flexibility, and stiffness. Traditional patterns like plain and twill weaves provide balanced and diagonal structures, respectively, each catering to distinct needs. As technology evolves, more intricate weave patterns are emerging, offering refined control over material properties.

Recent strides in carbon fabric technology emphasize manufacturing efficiency and cost reduction. Automated processes, including robotic weaving and automated lay-up systems, ensure precision and consistency in crafting complex shapes, diminishing the reliance on manual labor. The quest for sustainability drives innovations such as recycling techniques and eco-friendly binders and resins. These advancements aim to augment accessibility and broaden carbon fabric's application scope, rendering it more viable across industries and products.

In conclusion, carbon fabric embodies the exceptional attributes of carbon fibers in a woven form, presenting a material characterized by unparalleled strength, lightweight composition, and malleable traits. The synergistic interplay of these attributes has led to its integration in sectors spanning aerospace to sports and beyond. As production techniques advance and sustainable practices gain traction, carbon fabric's influence is poised to burgeon, reshaping possibilities in industries reliant on high-performance materials.

Carbon Fiber Fabric

English

English عربى

عربى 中文简体

中文简体 Languages

Languages