In chemical production, due to the presence of a large number of flammable and explosive chemicals, can PTFE Fiberglass Fabric be used as a protective material to make work clothes, protective covers, etc., to protect workers from the threat of fire and explosion?

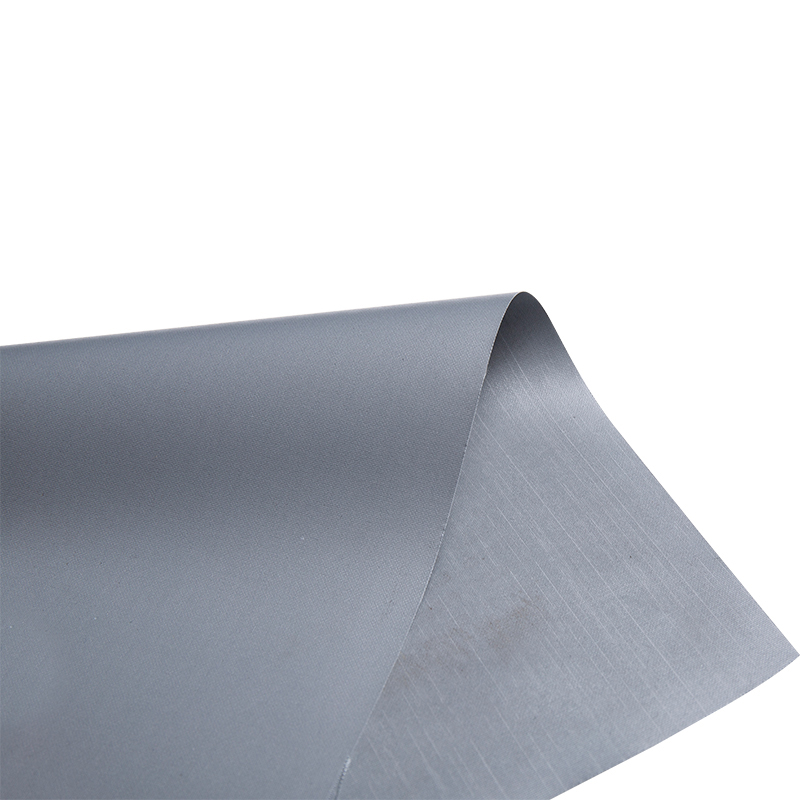

In chemical production, due to the presence of a large number of flammable and explosive chemicals, it is crucial to choose appropriate protective materials to ensure the safety of workers. PTFE Fiberglass Fabric, also known as Teflon fabric or polytetrafluoroethylene coated fiberglass fabric, is a high-performance, versatile composite material.

First of all, judging from the performance characteristics of PTFE Fiberglass Fabric, it does have some significant advantages, making it potentially suitable for protective material applications. For example, PTFE Fiberglass Fabric has excellent weather resistance and aging resistance, and can maintain stable performance between extremely low temperatures (-196°C) and extremely high temperatures (350°C). In addition, it is non-adhesive and does not tend to stick to anything, which is great for preventing chemical residue and build-up.

However, there are other key factors to consider when determining whether PTFE Fiberglass Fabric is suitable as a protective material in chemical production. For example, PTFE may release the toxic gas hydrogen fluoride at high temperatures (over 200°C), so corresponding protective measures need to be taken when using it. Additionally, while PTFE Fiberglass Fabric has excellent chemical resistance, it is not completely immune to all chemicals, especially under extreme conditions.

For protective equipment such as work clothes and shields, in addition to the performance of the material itself, factors such as its structure, layout and strength also need to be considered. For example, protective shields should have sufficient strength and stiffness to ensure workers are protected from injury in an emergency. In addition, protective equipment should be designed to provide maximum protection without impeding workers' operations.

PTFE Fiberglass Fabric, as a high-performance composite material, has certain application potential in chemical production. However, whether it is suitable as a protective material for making work clothes, protective shields, etc. still needs to be evaluated and selected based on the specific working environment and conditions. During the selection and use process, the material's performance characteristics, usage limitations, and design requirements for protective equipment should be fully considered to ensure worker safety.

English

English عربى

عربى 中文简体

中文简体 Languages

Languages